Dental lab, Dental Laboratory, Excel Dental Lab - In search of excellence in dental laboratory

Excel Dental Lab Co., Ltd.

“ In search of excellence in dental laboratory ”

Dental lab, Dental Laboratory, Excel Dental LabProducts

+662 277 6343, +662 277 6344, +6684 644 5865

+662 277 6343, +662 277 6344, +6684 644 5865

dental lab, dental Laboratory

Digital CAD/CAM Center » Digital CAD/CAM Center

Digital CAD/CAM Center

Excel Dental Lab Digtital CAD/CAM Center

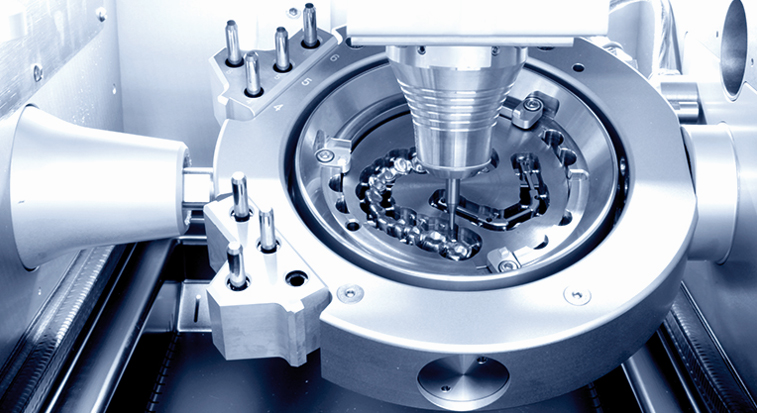

At Excel Dental Lab, we have embraced the latest digital technology in dentistry while still respecting tradition. With our leading-edge CAD/CAM system and technical expertise, we can process digital files from your oral scanners anywhere in the world. Today’s technology helps shorten the distance and downsize the world where we live and work, especially in dental industry. Our digital CAD/CAM center inside our laboratory is a state-of-the-art facility managed by a team of the most experienced digital and CAD/CAM technicians. By combining the latest digital technology with skilled craftsmanship, we will deliver consistent quality and value.

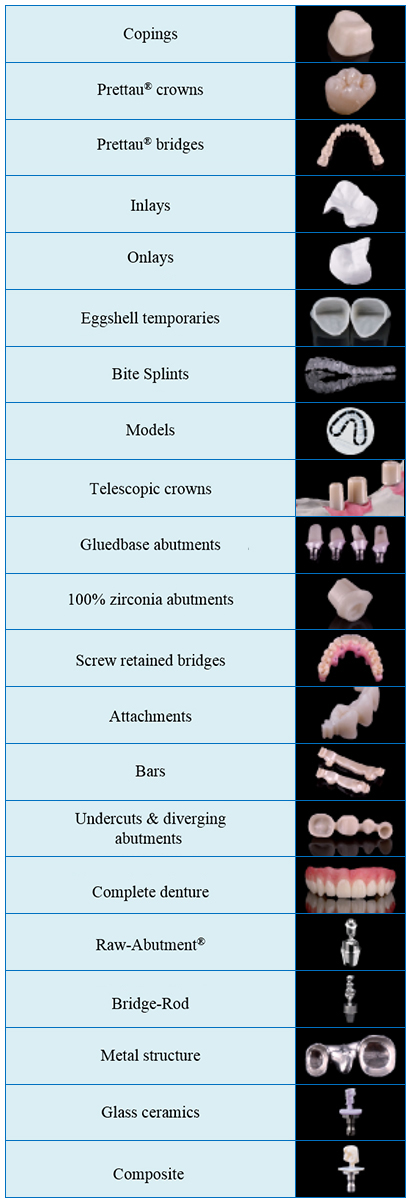

Excel Dental Lab installed the newest and complete CAD/CAM system from Zirkonzahn, Italy. The innovative scanner S600 ARTI is fully automated optical structured-light scanner in combination with specialized scanning software. Precision is ≤ 10 μm. The M1 milling machine is the latest 5+1 axes simultaneous milling unit with wet and heavy metal functionality. It can mill various materials such as zirconia, anterior & posterior full zirconia, custom implant abutment, screw-retained bridge, titanium, glass ceramic, resin, sinter metal, chrome cobalt, raw abutment etc. It also incorporates the cutting-edge wet milling technology. The software package and modules open up a possibility to design and produce all types of restorations we can imagine. It could be the very basic zirconia crown & bridge for veneering with porcelain, or entirely/partially full zirconia zirconia. It could be custom implant abutment or full arch screw-retained bridge. Or even complicated work like bar attachment or hybrid superstructure.

Milling process of real case at Excel Dental Lab

Complete CAD/CAM system

Range of applications

*Subject to availability of software modules

Millable materials with full equipment

Digital Impression Scans

Dentists are now leveraging their investments in chairside oral scanner systems by partnering with digitally enabled laboratories to streamline their workflow and reduce the time and cost of treatment. Today at Excel Dental Lab, we are happy to accept digital impression scans from you in open STL format. With digital impressions, you’ll save on impression material, trays and one-way shipping to Thailand. But you don’t compromise on the quality and service you will get from us. We still give full attention, skillful craftsmanship, and esthetic value on every single case which goes through our lab. The technicians who design your prosthesis digitally are the same technicians who can fabricate your crown by hand but they are also equipped with additional computer skillsets and specialized training in CAD/CAM. After all, CADCAM is not only about computer knowledge, but it also requires the same in-depth understanding of technical dental work.

3 Possibilities of working digitally:

1) Overseas clients have a possibility of sending us physical impressions or models in traditional way. Then we scan from model/impression, and proceed to designing, milling crowns digitally on our systems.

2) Clients also can send us digital files from oral scanner (in open STL format). Then we process the files in our system and produce full-contour restoration without model, such as monolithic zirconia (anterior & posterior) or glass ceramic. Lithium disilicate glass ceramic is currently available in e.max CAD, Vita Suprinity, and Mark II. Full-contour composite resin and PMMA are also possible.

3) Clients can send us digital files from oral scanner. Then we process digital files to produce a physical model in resin, and fabricate all types of restorations including PFM, full gold crown, all-ceramic, porcelain-layered zirconia etc. Note that resin-based models will be produced by 3D digital printer and will incur additional cost. A model will enable us to apply porcelain veneering and check fitting/contacts/occlusion in a usual manner.

Our lab is working with various intraoral scanners, namely…

3Shape Trios: You can link directly to our lab via 3Shape Communicate system

Carestream: You can link directly to our lab via CS Connect system

Medit: You can link directly to our lab via Medit Link system

iTero: You can link directly to our lab via My AlignTech system

Cerec/Sirona: You can link directly to our lab via Sirona Connect Case Center system

For all above options, search for ′Excel Dental Lab′ or ′contact@excel-dental.com′, then create connection/partnership.

3M: You have to export STL file and send the STL file directly to us by email or file transfer service (DropBox, GoogleDrive, wetransfer etc.)

Other scanners: You have to export STL file and send the STL file directly to us by email or file transfer service (DropBox, GoogleDrive, wetransfer etc.)

Lab cases »

Copyright © 2024-2025 Excel Dental Lab Co., Ltd. All rights reserved.